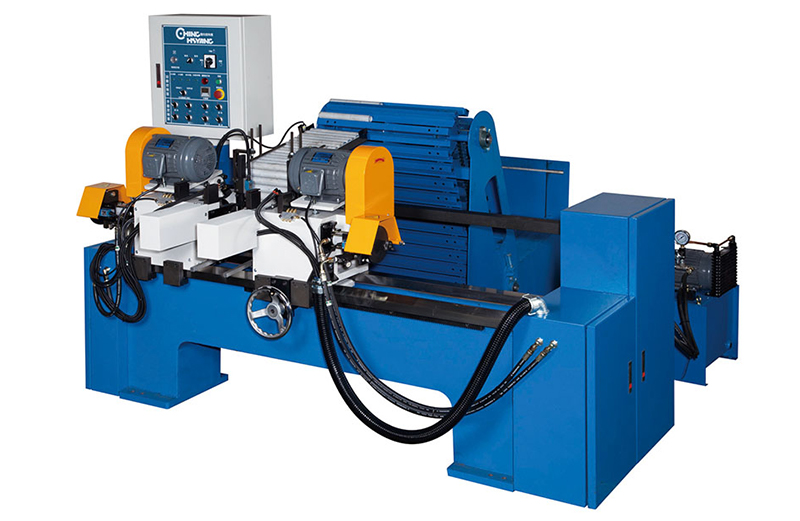

Double head chamfering machine CH-60-3A, CH-60-3AB, CH-80-3A, CH-80-3AB

1.The inner and outer corners and the surface of the round tube can be trimmed at one time, quickly and accurately.

2.The cutter head uses commercially available blades, which are easy and quick to replace.

3.Two-stage feed, smooth idle stroke, and the working stroke can be stably adjusted according to the cutting amount.

4.With manual and automatic functions, it is convenient to correct and adjust the machine.

5.Special automatic positioning device, which can automatically position, feed, chamfer, and fine-tune the length tolerance.

6.Oil mist lubricated cooling system increases blade life without chipping.

7.There is a pause adjustment switch at the end of the feed to ensure that the cut surface is flat and the workpiece straightness is correct.

8.The front axle seat is equipped with phosphor bronze bushing to prolong the service life of the machine.

_______________________________________________________________________________________________

Standard accessories

1.Main engine and transmission system

2.PLC automatic electronic control system

3.hydraulic system

4.2 standard cutter heads, 3 cutter bases, 3 blades

5.Fixture 1 set

6.Tool locking sheet hand

7.toolbox

8.Cutting Oil Spray System

_______________________________________________________________________________________________

special accessories

1.special cutter head

2.Clamps of different sizes

3.special tool holder

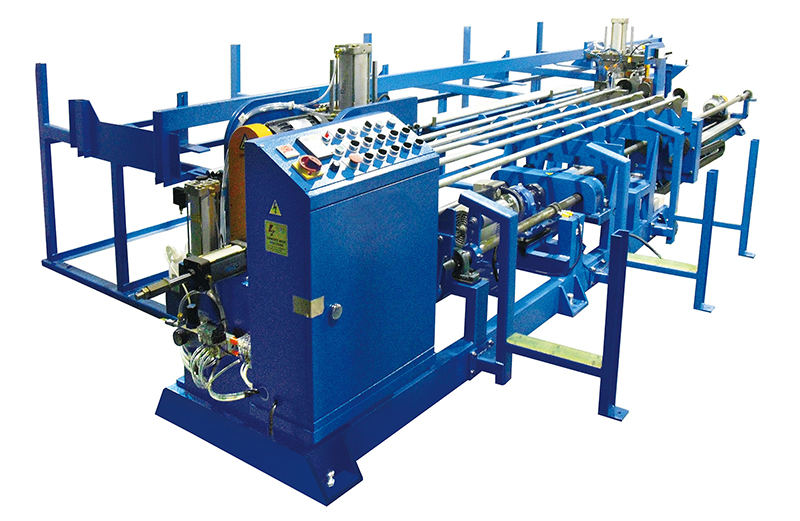

4.Automatic feeding system

5.R angle blade

6.Inverter

Detailed description

1.The inner and outer corners and the surface of the round tube can be trimmed at one time, quickly and accurately.

2.The cutter head uses commercially available blades, which are easy and quick to replace.

3.Two-stage feed, smooth idle stroke, and the working stroke can be stably adjusted according to the cutting amount.

4.With manual and automatic functions, it is convenient to correct and adjust the machine.

5.Special automatic positioning device, which can automatically position, feed, chamfer, and fine-tune the length tolerance.

6.Oil mist lubricated cooling system increases blade life without chipping.

7.There is a pause adjustment switch at the end of the feed to ensure that the cut surface is flat and the workpiece straightness is correct.

8.The front axle seat is equipped with phosphor bronze bushing to prolong the service life of the machine.

_______________________________________________________________________________________________

Standard accessories

1.Main engine and transmission system

2.PLC automatic electronic control system

3.hydraulic system

4.2 standard cutter heads, 3 cutter bases, 3 blades

5.Fixture 1 set

6.Tool locking sheet hand

7.toolbox

8.Cutting Oil Spray System

_______________________________________________________________________________________________

special accessories

1.special cutter head

2.Clamps of different sizes

3.special tool holder

4.Automatic feeding system

5.R angle blade

6.Inverter

Specification data

| model | CH-60-3A | CH-60-3AB | CH-80-3A | CH-80-3AB |

|---|---|---|---|---|

| host motor | 2 x 2HP | 2 x 2HP | 2 x 3HP | 2 x 3HP |

| Spindle speed |

A: 4P-2500/1430 rpm B: 6P-1740/1000 rpm |

A: 4P-2500/1430 rpm B: 6P-1740/1000 rpm |

A: 6P-930/730 rpm B: 8P-660/520rpm |

A: 6P-930/730 rpm B: 8P-660/520rpm |

| Pipe diameter | 12-60mm | 12-60mm | 25-80mm | 25-80mm |

| long type |

A: 150-1000 nm (standard) B: 150-1500mm C: 150-2000mm |

- |

A: 150-1000 nm (standard) B: 150-1500mm C: 150-2000mm |

- |

| short material | - | 25-230mm | - | 25-230mm |

| Hydraulic horsepower | 2 HP | 2 HP | 2 HP | 2 HP |

| Use air pressure | 4-6 kg/cm2 | 4-6 kg/cm2 | 4-6 kg/cm2 | 4-6 kg/cm2 |

| Machine size (mm) | 1130x2230x1600mm | 1550x2100x1600 mm | 1130x2100x1600mm | 1550x2100x1600 mm |

| Machine weight (kg) | 1310kgs | 1310kgs | 1450kgs | 1450kgs |